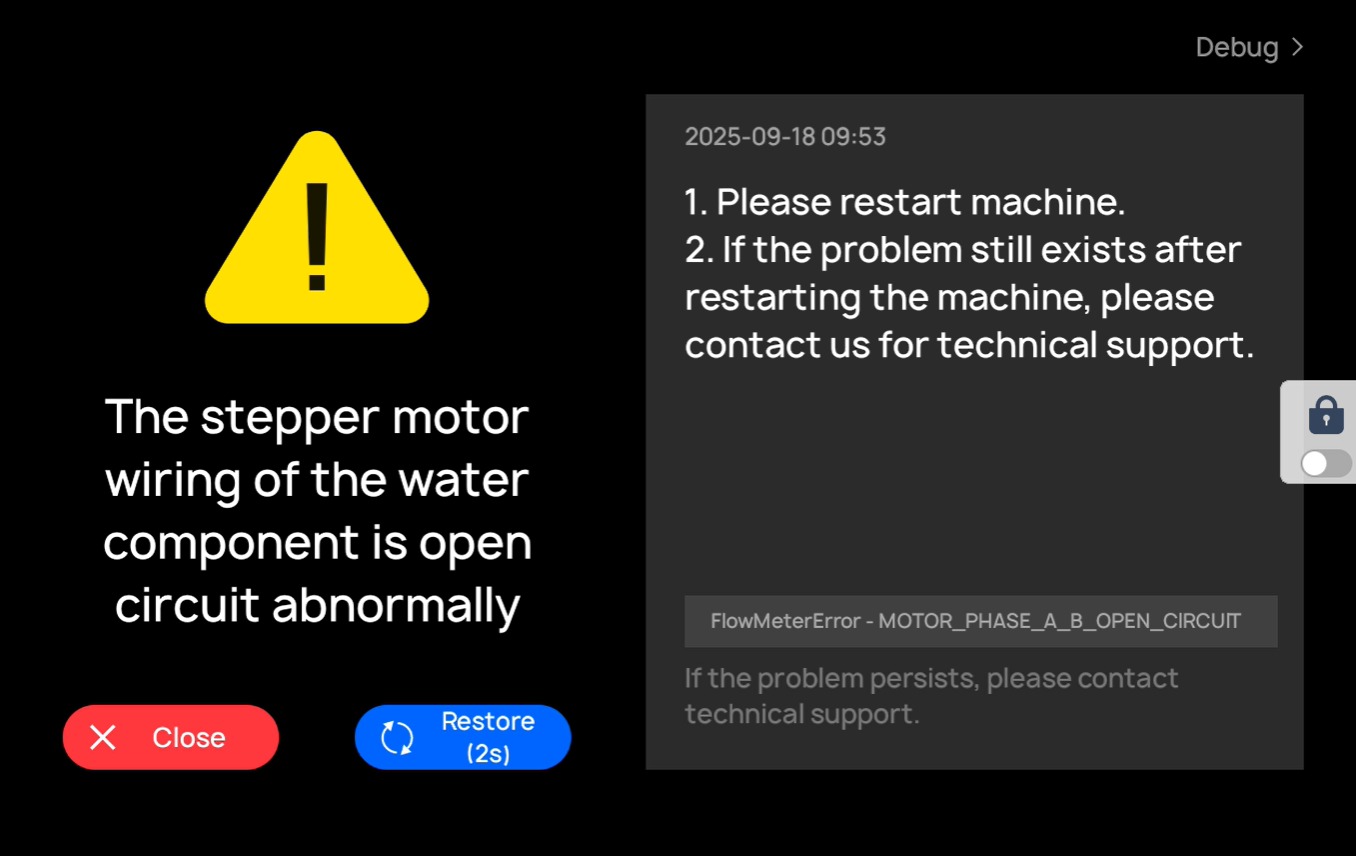

CC1 - STEPPER MOTOR WIRING ERROR

The Stepper Motor Wiring Error typically indicates a connection issue between the water component and the mainboard (CT1). Follow the steps below to diagnose and resolve the problem.

MT1 - ONE OR BOTH FRONT BRUSHES NOT SPINNING

When running the Robot, the brush or brushes are not spinning

CC5 - FORCING MANUAL DRIVING CAPABILITIES

If the Robot freezes or locks up, you can put it in manaual mode to drive it out of the way

CC5 - RESTRICTIVE MOVEMENT; WONT GO FORWARD

The Robot will only travel backwards. Even when placing in manual mode, it wont go forward

CC1 - DIFFERENT STYLE OF BRUSHES

The CC1 went through a refresh, making improvements to the Brush Deck. This has caused two different size of brushes being used in the CC1.

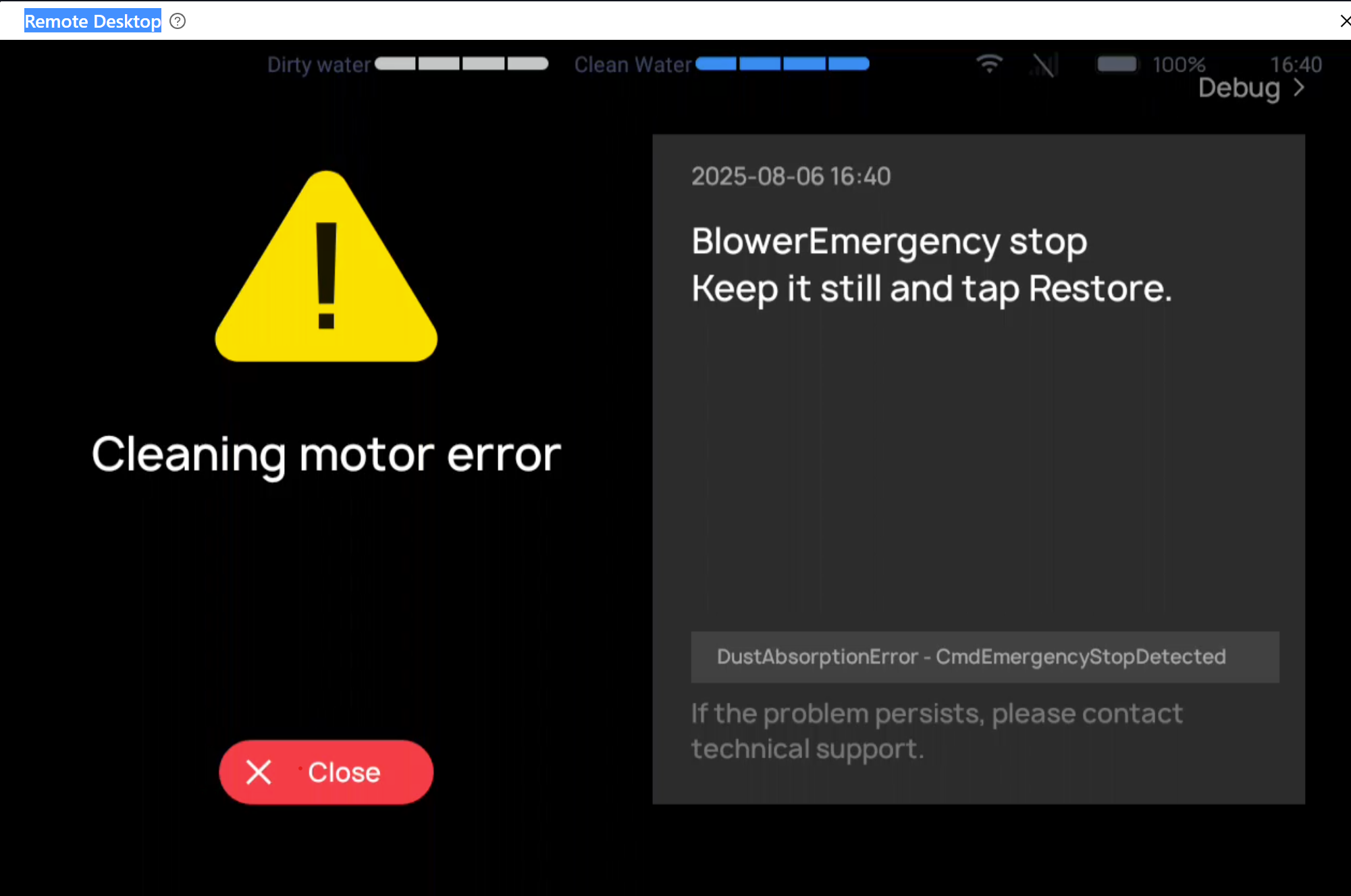

CC1 - BLOWER EMERGENCY STOP – CLEANING MOTOR ERROR

This error means the e-stop circuit disconnected at the CT2 board. causing the fan to trigger an e-stop error. It is possible that the water might have got into board cabin. Follow the steps below to troubleshoot the error.

CC1 - SETTING UP AN ADVERTISEMENT PAGE ON THE BOT SCREEN

Follow the steps below to set up and display custom advertisements on the BoT’s screen.

CC1 - SOFTWARE CURRENT OVER ERROR

The “Software Current Over” error is typically caused by motor overcurrent, which is related to either the roller brush motor or the hub motor. In most cases, this issue is due to entanglements or obstructions within the brush assembly that restrict motor movement and cause excessive current draw.

CC1 - CLEANING THE BRUSH CHAMBER

This article will guide you through cleaning the Brush Chamber. It is only available for the Grey Scale Version and above.

CC1 - DIRTY TANK FALSELY REPORTING FULL OF SEWAGE

Robot is saying dirty tank is full when it is empty. How to troubleshoot

CC1 - WORKSTATION ERROR OF ADD WATER

To troubleshoot water refill failures at a workstation, check water source pressure and valve setups (tap, check valve, solenoid, and pressure reducing valves).

CC1 - WORKSTATION ERROR CODE 370

How to troubleshoot docking problems onto workstation. Getting error code 370

CC1 - WHEEL RIGHT ERROR BUMP SENSOR RESET PROCEDURE

How to troubleshoot a Wheel Right bump sensor error and disable the sensor trigger, including steps for inspecting the bump sensor and resetting the pressure threshold that may be causing the error.

CC1 - HOW TO CHANGE SQUEEGEE BLADES OF BACK ATTACHMENT

How to flip your squeegee blades to extend the life of the squeegee, or replace

CC1 - WHEEL LEFT AND OTHER MOTOR EXCEPTION ERRORS

These troubleshooting steps are used to diagnose and resolve motor-related faults in the Pudu CC1 robot, specifically when the unit reports errors such as:

-

INTERNAL_ERROR -

OUT_LOSE_PHASE INTERNAL_ERROR

CC1 - NEW WATER DISBURSEMENT PLATE

The water disbursement plate may be positioned above the brush deck for easier removal. Instructions on how to remove water plate and open up to clean out for maintenance.

CC1 - ENCODER BRUSH ERRORS - UNDULATE; ETC

This process systematically addresses encoder brush faults, beginning with basic debugging and escalating to hardware replacement if necessary.

CC1 - CLEANING WATER DISBURSEMENT PLATE

How to remove and clean water disbursement plate that sits above the brush deck

CC1 - BLACK OR BLANK SCREEN TROUBLESHOOTING

Robot is not turning on its screen. Screen appears to be blank or black, troublshooting steps.

CC1 - ERROR RGBD CAMERA NOT FOUND

Scenario: The CC1 robot displays an RGBD camera fault. Objective: Systematically identify and isolate the source of the RGBD fault using basic tools and interface commands.

MT1 - RIGHTEDGESWIPEERROR - SPEED DEVIATION TOO LARGE

Check side brush installation and swap sides to see if the error follows the brush. If not, test for motor resistance and inspect the installation plate for wear. Finally, check motor current—if over 3.5A, replace the motor—then recheck system functionality.

CC1- OTHER EXCEPTIONS AND CLEANING MOTOR ERROR

If “Other exceptions” and “Cleaning motor error” persist after CT1 replacement, check for physical damage, verify CT1 functionality via voltage and CAN logs (should be >24V), and inspect CT4 for corrosion or voltage issues (24–28V). Replace components as needed.

TEST BLOG - PLEASE IGNORE

How to troubleshoot a CC1 error/malfunction

CC1 - SELF INSPECTION FAILED - OS INIT

When starting up the Robot you encounter a Self Inspection failed error. This article will help deal with specifically the "code - 100, msg is connect can bus fail" error

CC1 - INCREASE WATER OUTPUT FOR SCRUBBING

Increasing water output can help address floor cleaning issues on surfaces with heavy dust, significant dirt, or high absorbency. The increased output can also help address clean marks left behind from the Robot.