SH1 - OVERSPEED ERROR (FAN_INTER_OVER_SPEED_ERR)

This article explains the common causes of the SH1 overspeed error. The SH1 overspeed error is typically caused by airflow restrictions.

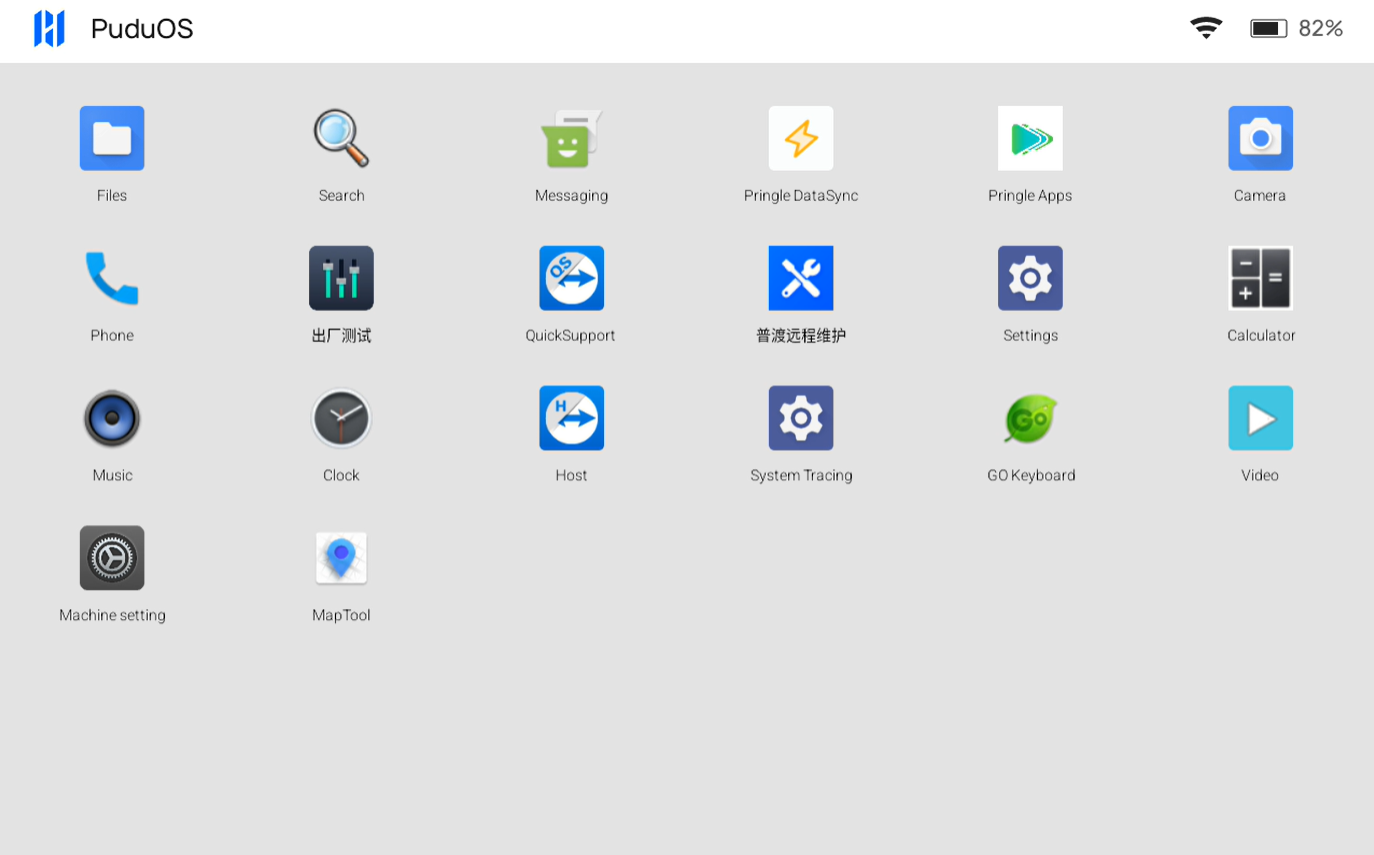

BELLA - ACCESSING THE ANDROID HOME MENU

You may need to access the Android home screen remotely in order to do application maintenance. Such as updating, installing or un-installing an application. Sometime these application need to be signed into directly from the app. In order to do this you will need access to the Android application tray menu directly. This is the remote adb command process of how to get to this screen.

CC1- REMOVING AND RE-INSTALLING SUCTION HOSE

If you experience poor suction and flushing the suction hose does not improve the issue, or if you discover or suspect a torn hose, the unit may need to be partially disassembled to access the suction hose for inspection and replacement.

CC1 - CLEANING MOTOR ERROR - EDGESWIPEERROR- MOTOR STUCK

This article explains what causes the EdgeSwipeError – Motor Stuck error and how to temporarily resolve it by disabling the side brush while operating in Scrubbing Mode.

CC1 - ACTIVATING THE STROBE LIGHT ON THE BOT

This article explains how to enable and configure the strobe light on supported BoT models. Follow the steps carefully to ensure the strobe light functions correctly.

CC1 - ESP32 ERROR

This article explains how to resolve an ESP32 Error by updating the ESP32 device configuration in the robot’s system menu. This change disables ESP32 detection when the hardware is not present or required.

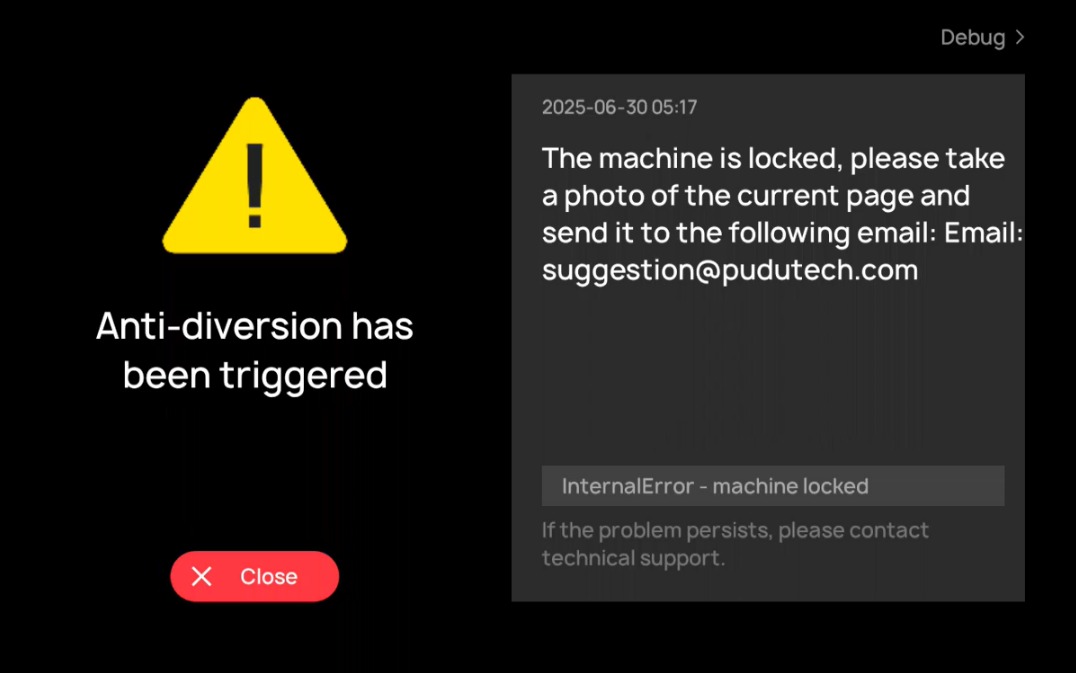

CC1 - ANTI DIVERSION TRIGGERED ERROR

The Anti-Diversion Error is triggered by the anti-diversion interface. This error generally occurs when the map has been modified while the robot is not connected to a network.

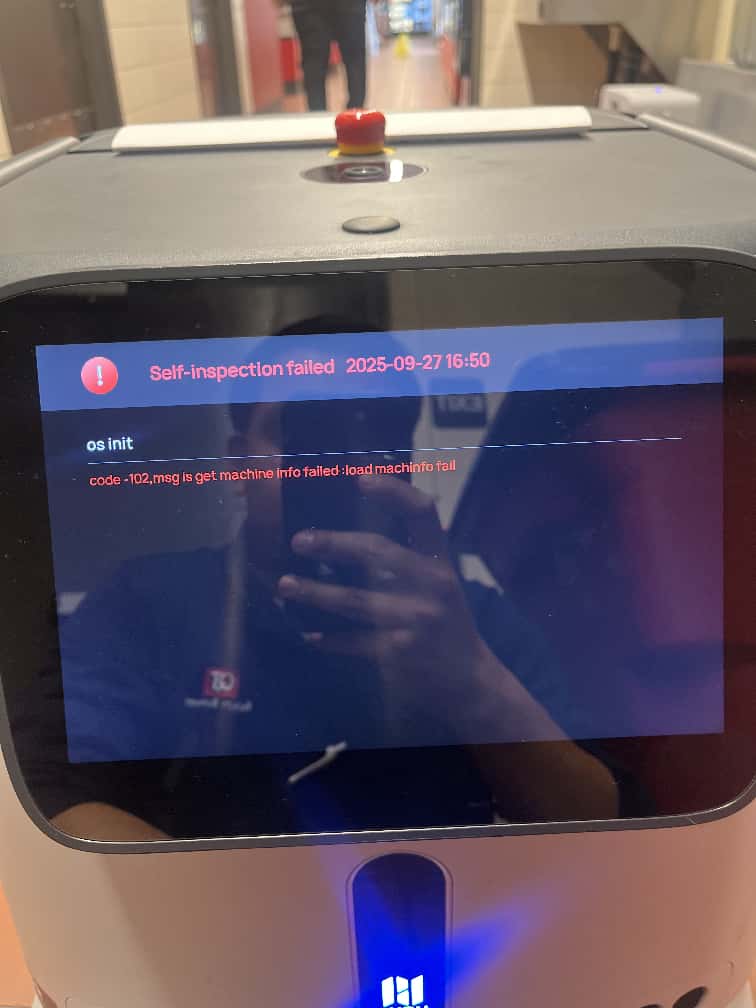

CC1 - OS INIT CODE - 102 ERRORS - GET MACHINE INFO AND LOADHARDWAREVERSION FAIL

This error message indicates a hardware communication failure involving components connected to the CT1 board, or a failure of the CT1 board itself.

.png)

CC3 - TRICKLE CHARGING THE BATTERY

This article explains the correct procedure for trickle charging a CC3 battery when it is drained below the recovery level of the standard charger.

BELLA - ERROR_BATTERY_PACK_COMM

Overview

ERROR_BATTERY_PACK_COMM indicates abnormal communication between the robot and its battery pack. This issue can be caused by loose cable connections, battery faults, board issues, or environmental interference such as static discharge or electromagnetic noise.

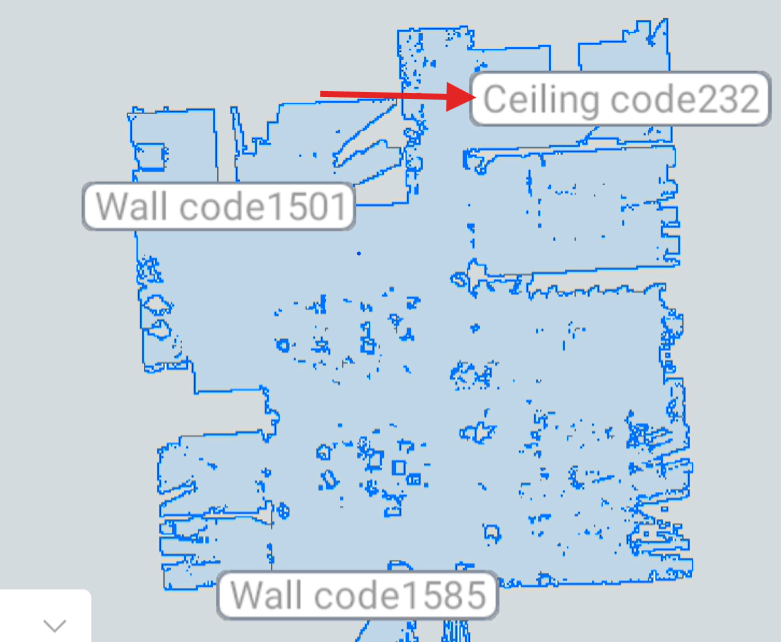

CC1- ADDING CEILING MARKERS TO A MAP

Ceiling and wall marker mapping solutions are available on the CC1. These solutions are based on the laser mapping system and can be enhanced by incorporating a small number of marker stickers to improve positional accuracy through integrated mapping.

CC1 - DEVICE STATUS ALERTS ON CONSUMABLES

If this message pops up on your machine, it’s basically the BoT tapping you on the shoulder and saying one of its consumable components needs attention. You can find all the gritty details in the Device Status menu, accessible right from the BoT’s homescreen.

CC5 - ADJUSTING CHARGING PILE DEPTH

This article explains how to adjust the AC Charge Stop Buffer setting on the CC3/CC5 BoT to improve alignment with the charging pile when the charging electrodes do not make proper contact.

CC5 - OBSTACLE HEIGHT DETECTION

Configuration guide for adjusting the Ground Segment Threshold.

The Obstacle Height Detection setting controls how sensitive the BoT is to low-height obstacles by adjusting the Ground Segment Threshold. Modifying this value changes how the robot interprets objects that are close to ground level.

CC1 – BATTERY PACK COMMUNICATION ERROR

Even if raw voltage is present, the robot needs that comms line active to get status, temperature, charge/discharge permissions, etc.When comm breaks, the CT4 refuses to initialize the system for safety reasons.

CC1- BOT WILL NOT POWER ON OR CHARGE TROUBLESHOOTING FLOW

This diagnostic process ensures precise identification of non-power issues in CC1 systems, helping technicians isolate whether the root cause is the adapter, CT4 board, battery circuit, or wireless charging assembly before replacing components.

CC5 - HOW TO CHANGE SQUEEGEE BLADES OF BACK ATTACHMENT

This guide walks you through the steps to replace or flip the squeegee blades on your CC5 unit’s back attachment. Follow the instructions below or watch the video tutorial for a detailed walkthrough.

MT1 - ACTIVATING FRONT LED LOWLIGHT RUNTIME LIGHT

The MT1 is equipped with a large blue or white front LED designed for low-light environments while the BoT is in operation.

Although the BoT does not require this light to navigate or perform tasks in the dark, the front LED provides illumination and visual awareness for staff members working nearby.

This safety feature helps alert personnel to the BoT’s presence and position during operation, enhancing visibility and preventing accidental interference with its path or functions.

FLASH - ELEVATOR ENTRY DETECTION OBSTRUCTION DISTANCE AND ELEVATOR OBSTRUCTION DETECTION RECOGNITION DISTANCE

This guide helps you understand and adjust the Elevator Entry Detection Obstruction Duration and Elevator Obstruction Detection Recognition Distance settings. These parameters determine how long and how far the robot will monitor for obstacles when entering or exiting elevators.

BELLA - LCD REPLACEMENT MODEL PART NUMBER DIFFERENCES

There are 4 different types of LCD screens for the Bellabot service model. If the screen needs to be replaced or repaired you will need to confirm which part number screen is needed before requisitioning or warranty requesting the part.

CC1 - BALL VALVE DRAIN DIAGNOSTIC VIDEO

This video provides a structured walkthrough for diagnosing and verifying the functionality of the CC1 wastewater (ball) valve system. It focuses on identifying whether issues stem from software control, hardware components, or mechanical blockages.

WALL MARKERS FOR THE PUDU BOT’S (NEW)

This help article have a new Wall Markers along with the codes for the PUDU BoT's.

WALL MARKERS FOR THE PUDU BOT’S (OLD)

This article contains the archived list of Old Wall Markers and their respective codes used in earlier PUDU BoT deployments.

CC1 - RGBD DISTORTION CAUSING NAVIGATIONAL ISSUES

This guide explains how to fix navigation problems caused by incorrect or corrupted RGBD camera settings. It walks you through checking the camera orientation, resetting the RGBD configuration, and removing a faulty system file so the robot can recalibrate and navigate normally again. A video and example images are included for quick reference.